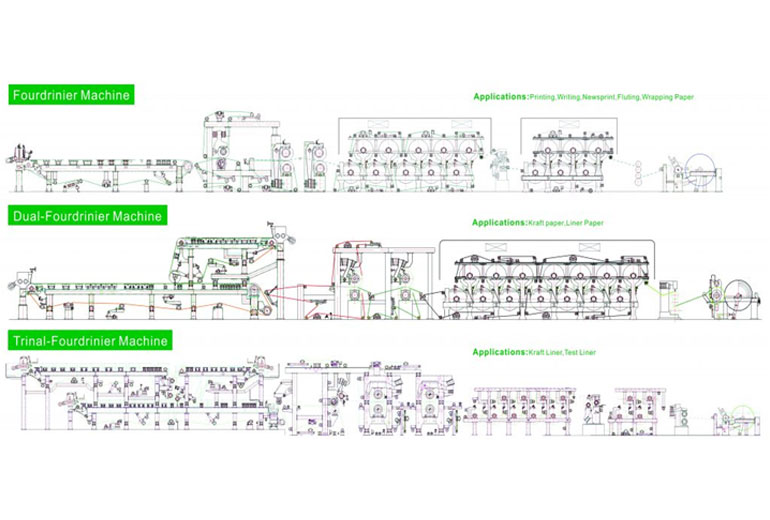

Fourdriner Paper Machine

Fourdriner Paper Machine

The Fourdrinier Machine is the basis for papermaking. There are four main sections used in the Fourdrinier Machine. Pulp preparations

The four Sections of the paper machine are:

- Wet end

- Press section

- Dryer section

- Calendar section

The first section is typically known as the wet end. Pulp may be delivered to the Fourdrinier machine in a slurry form (a mixture of fibre and water) directly from the pulping process. After refining the pulp is mixed with some of the following: sizing, fillers, colours, retention aid and waste paper called broke to a stock, and passed on. The stock enters the headbox and is fed onto wire mesh rollers with jets of pressurised water to make the fibres in the pulp face the same way. The water is removed along these belts.

The second section of the Fourdrinier machine is the press section, which removes the most water. The paper is fed over huge rolers that spin and remove the water from the paper.

The third section is the dryer section of the Fourdrinier machine. It dries the pulp by way of a series of steam-heated rollers that stretch the paper and help remove any moisture. Additional sizing agents, including resins, glue, or starch, can be added to the web to alter its characteristics. Sizing improves the paper's water resistance, decreases its ability to fuzz, reduces abrasiveness, and improves its printing properties and surface bond strength.

The fourth section is called the calender section and consists of a number of rolls, where pressure and heat is applied to the passing paper. Calenders are used to make the paper surface extra smooth and glossy. It also gives it a more uniform thickness. The pressure applied to the web by the rollers determines the finish of the paper. After calendering, the web has a moisture content of about 6%. It is wound onto a roll called a tambour, and stored for final cutting and shipping.

Technical data:

- Raw material: Recycled paper,Virgin pulp

- Output paper: Kraft paper/Corrugated paper/Writing paper/Copy paper,etc

- Weight: 40-300gsm

- Wire: up to 5 wires(5 layers)

- Net paper width: up to 5000mm

- Capacity: up tp 500T/D

- Work speed: up tp 500m/min